Advancing the construction industry with environmentally responsible equipment solutions and rigorous compliance standards

Building a greener future through responsible equipment sourcing and operation

At IR Construction Equipment Sourcing, we recognize that the construction industry accounts for nearly 40% of global CO₂ emissions. That's why we've made sustainability a cornerstone of our operations. Our comprehensive approach spans from equipment selection to end-of-life recycling, ensuring minimal environmental impact while delivering peak performance for your projects.

We prioritize Tier 4 Final and Stage V compliant machinery with advanced emissions control systems, reducing particulates by up to 90% compared to older models. Our electric and hybrid equipment options deliver zero on-site emissions.

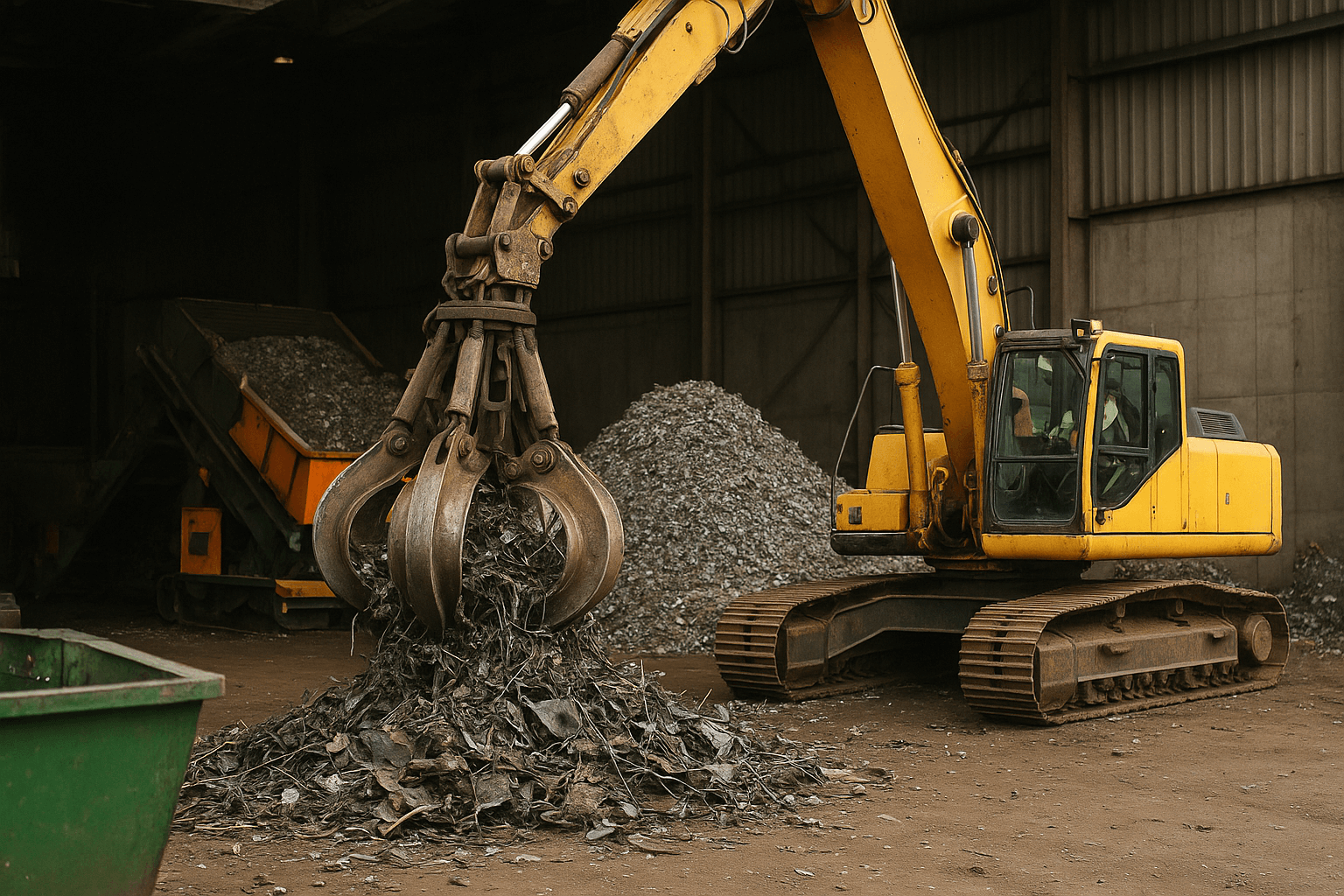

Our equipment refurbishment program extends machine lifespan by 8-12 years, reducing raw material consumption. We partner with certified recycling facilities to achieve over 95% material recovery rates for end-of-life equipment.

All shipments include CO₂ offset contributions through verified programs. Our route optimization technology reduces transport emissions by 15-25%, and we're converting 30% of our fleet to alternative fuel vehicles.

Ensuring your equipment meets all international regulatory requirements

Full compliance with the strictest global standards

Meeting stringent operational safety requirements

Adherence to hazardous substance restrictions

Our rigorous 6-step process for responsible equipment procurement

Comprehensive audits of all manufacturers against 78 sustainability and labor practice criteria, including environmental management systems, worker safety protocols, and ethical sourcing policies.

Lifecycle analysis to evaluate energy consumption, emission profiles, noise levels, and material composition to identify the most sustainable options for each application.

Third-party testing and certification validation to ensure all equipment meets destination country regulations and international standards.

Our proprietary scoring system (1-5 leaf rating) assesses each machine's environmental impact throughout its lifecycle, from manufacturing to disposal.

Detailed emissions analysis including manufacturing, transportation, and projected operational impacts with offset recommendations.

Annual supplier re-evaluations and equipment performance tracking to ensure ongoing compliance with evolving standards.

Innovative solutions to reduce environmental impact without compromising performance

Deployment of 22-ton electric excavators with rapid charging capabilities for a sensitive urban development project, achieving 100% emission-free operation while matching diesel performance metrics.

Implementation of the region's first hybrid diesel-electric tower cranes for a high-rise development, reducing fuel consumption by 43% and noise pollution by 60% compared to conventional models.

Retrofitting 38 heavy equipment units to operate on HVO (Hydrotreated Vegetable Oil) biofuel, achieving 90% reduction in greenhouse gas emissions across a major infrastructure project.

Our sustainability experts will help you select equipment that meets your environmental goals without compromising performance or budget.

Get Your Custom Sustainability Plan